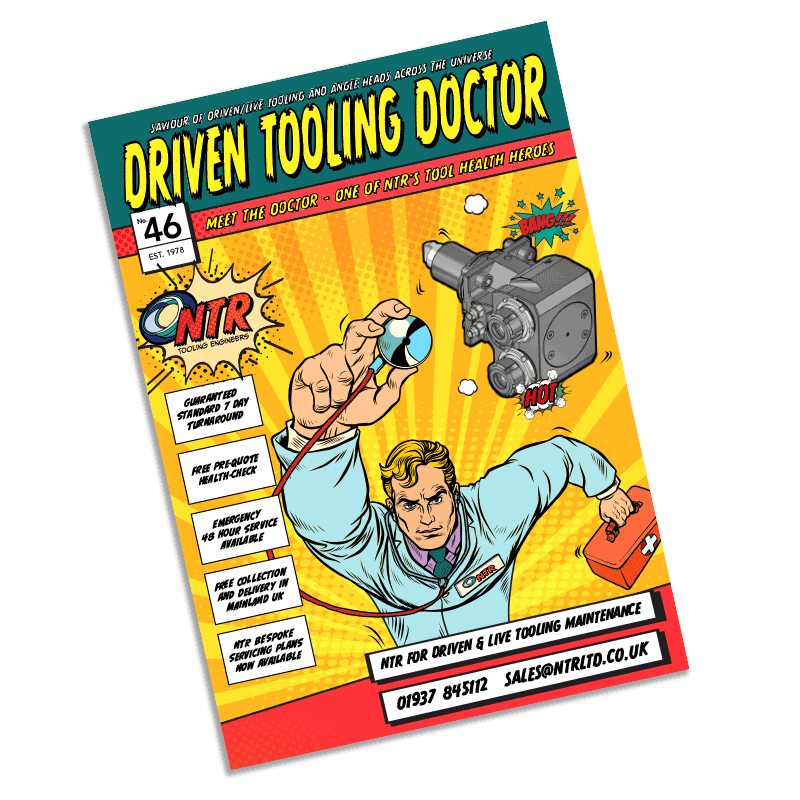

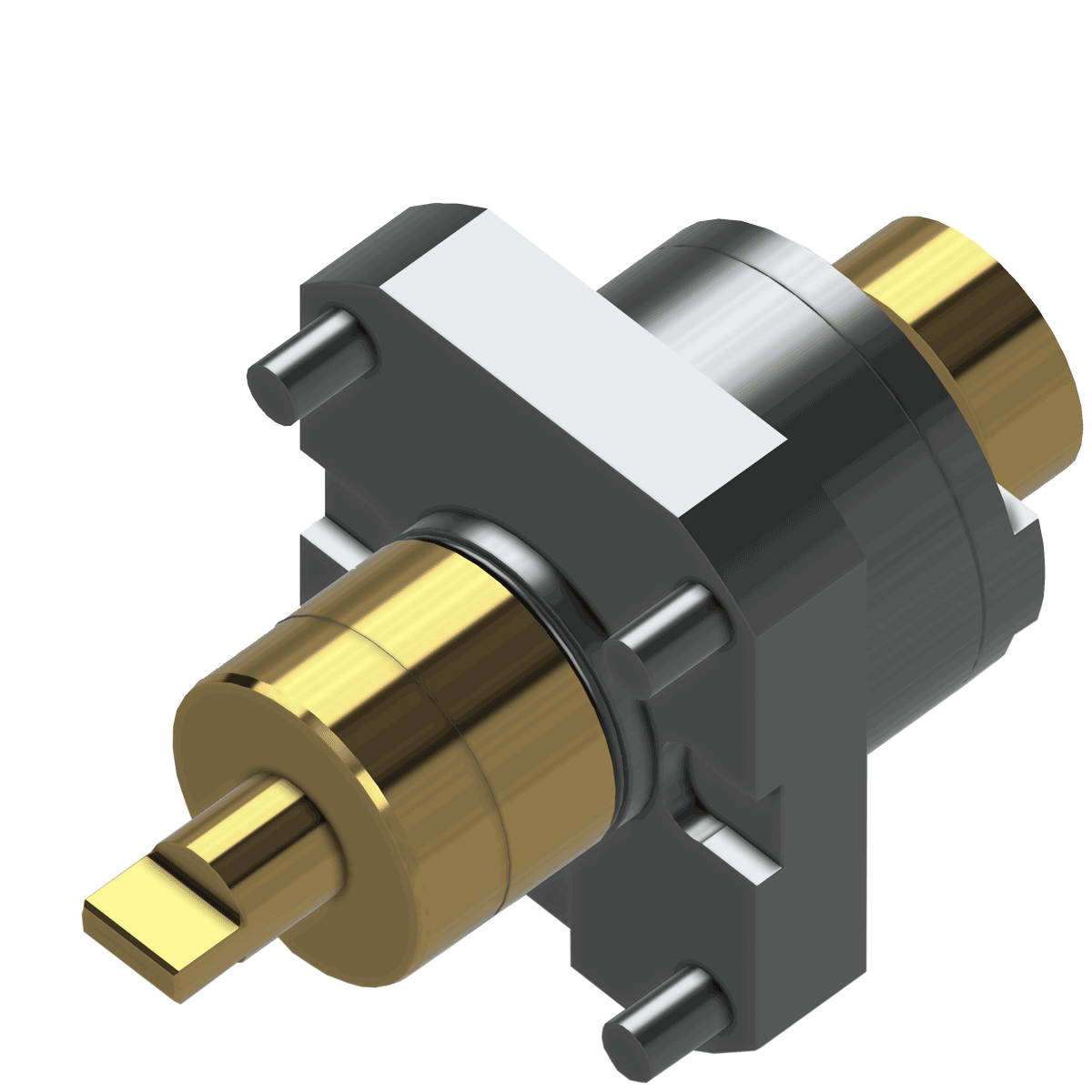

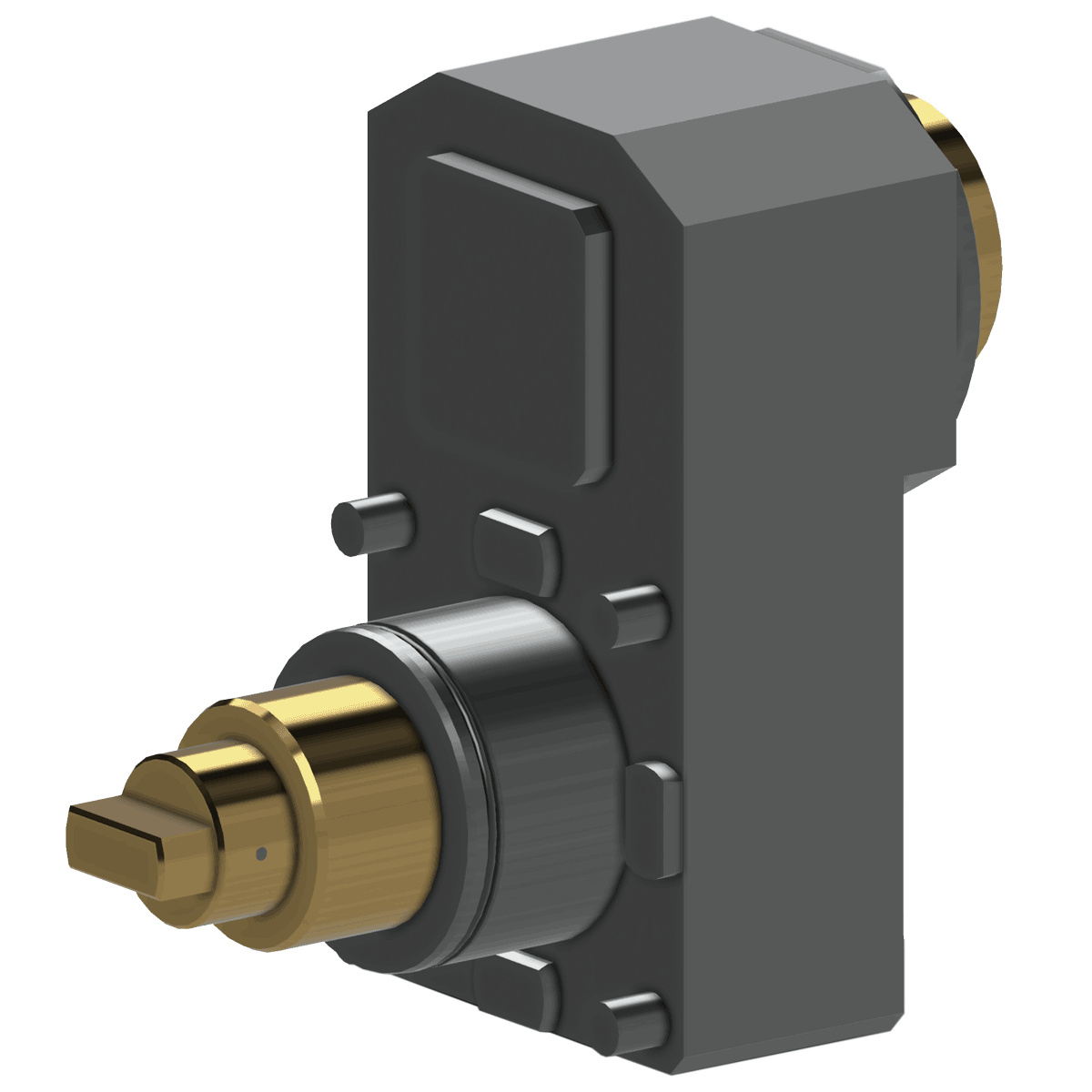

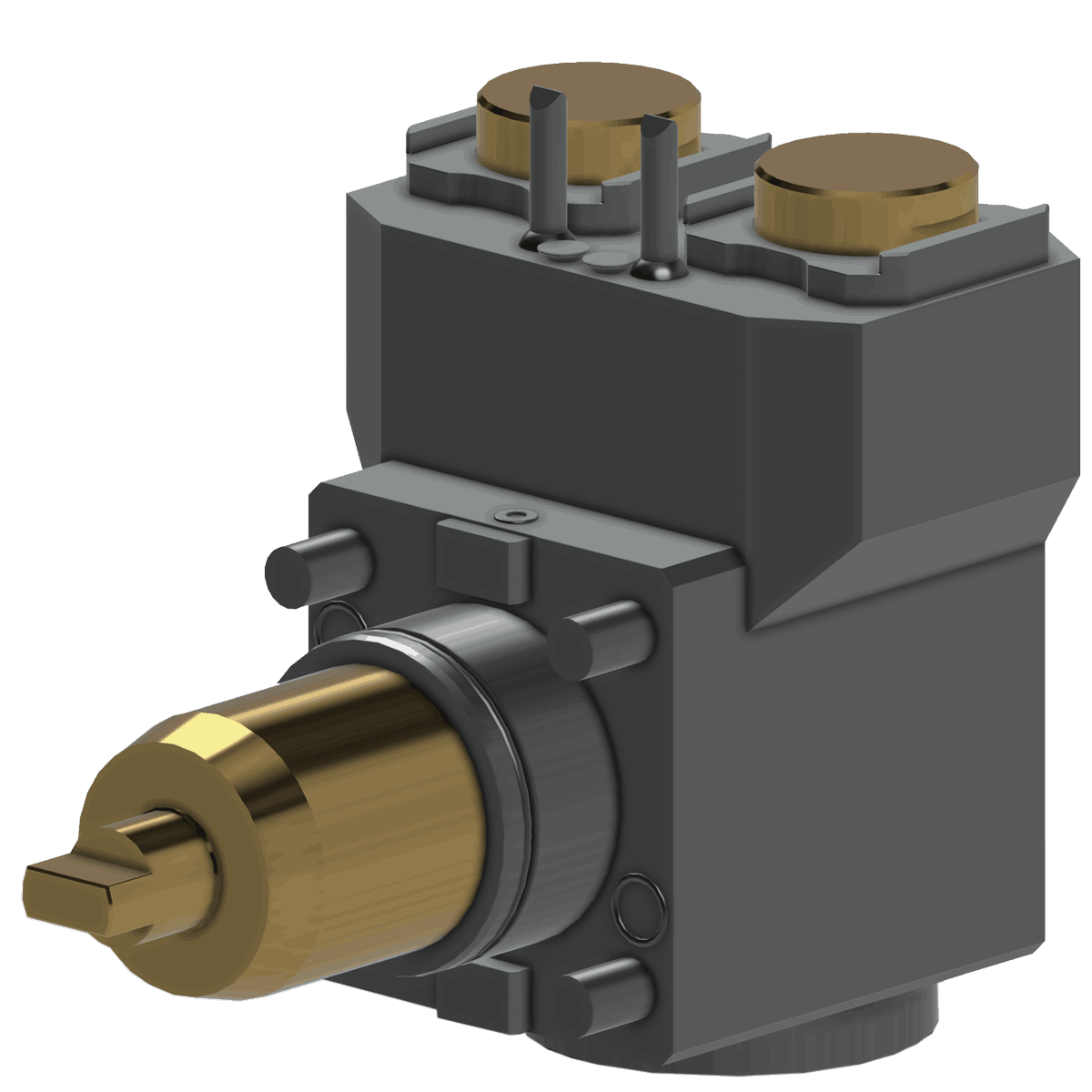

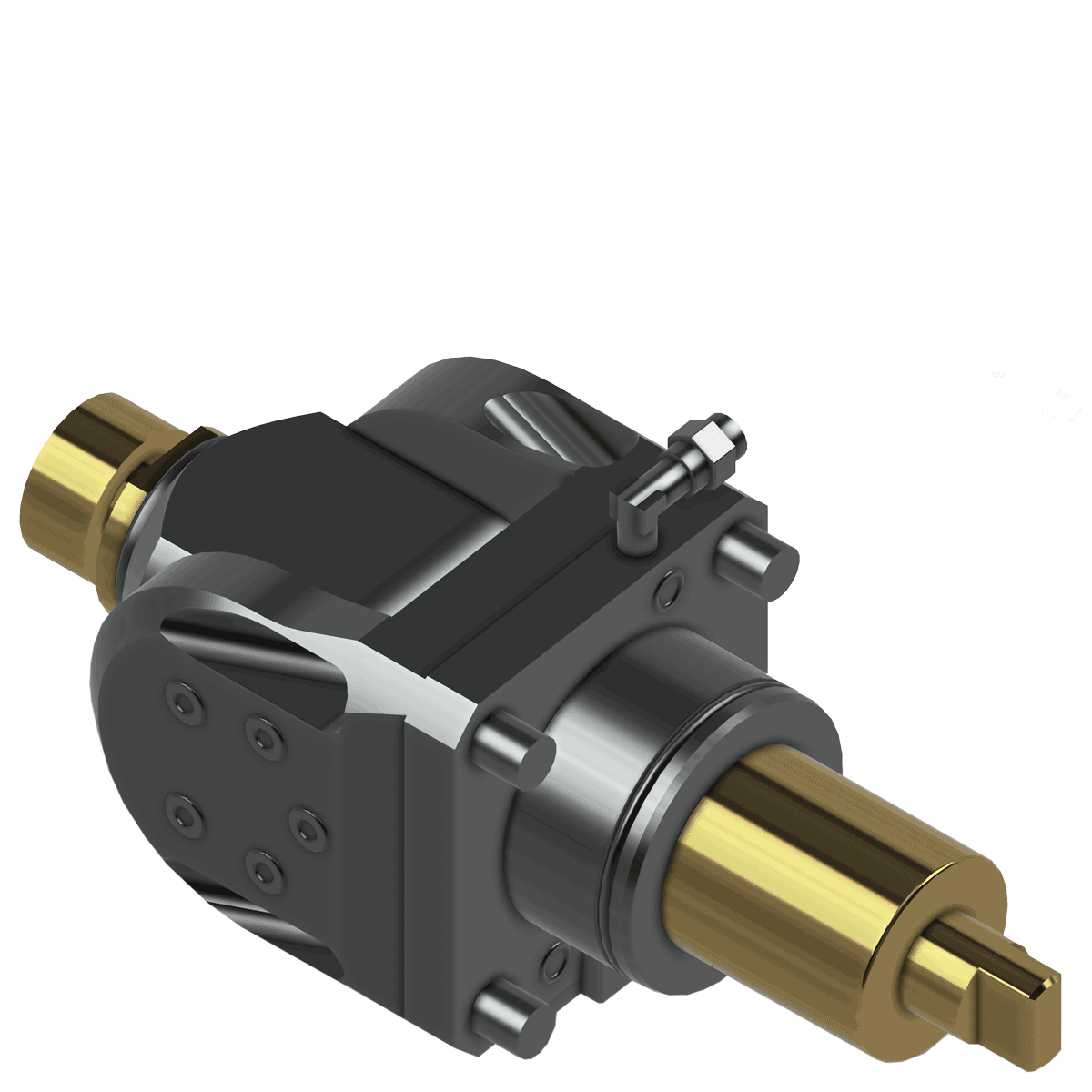

Looking for Live Tooling repair, maintenance and servicing?

At the heart of a well-run manufacturing facility is maintenance, and that’s how the Driven Tooling Doctor can help you. Not only is our repair service second-to-none, we also offer bespoke Servicing Plans to reduce the chance of breakdowns before they happen. Contact us today to find out how we can be the Tool Health Heroes, for your business. Call today 01937 845112.

- Guaranteed standard 7 day turnaround

- Free pre-quote health-check

- Emergency 48 hour service available

- Free collection and delivery in Mainland UK

- NTR bespoke Servicing Plans now available

- NTR Service & Repair

- Servicing Agreements

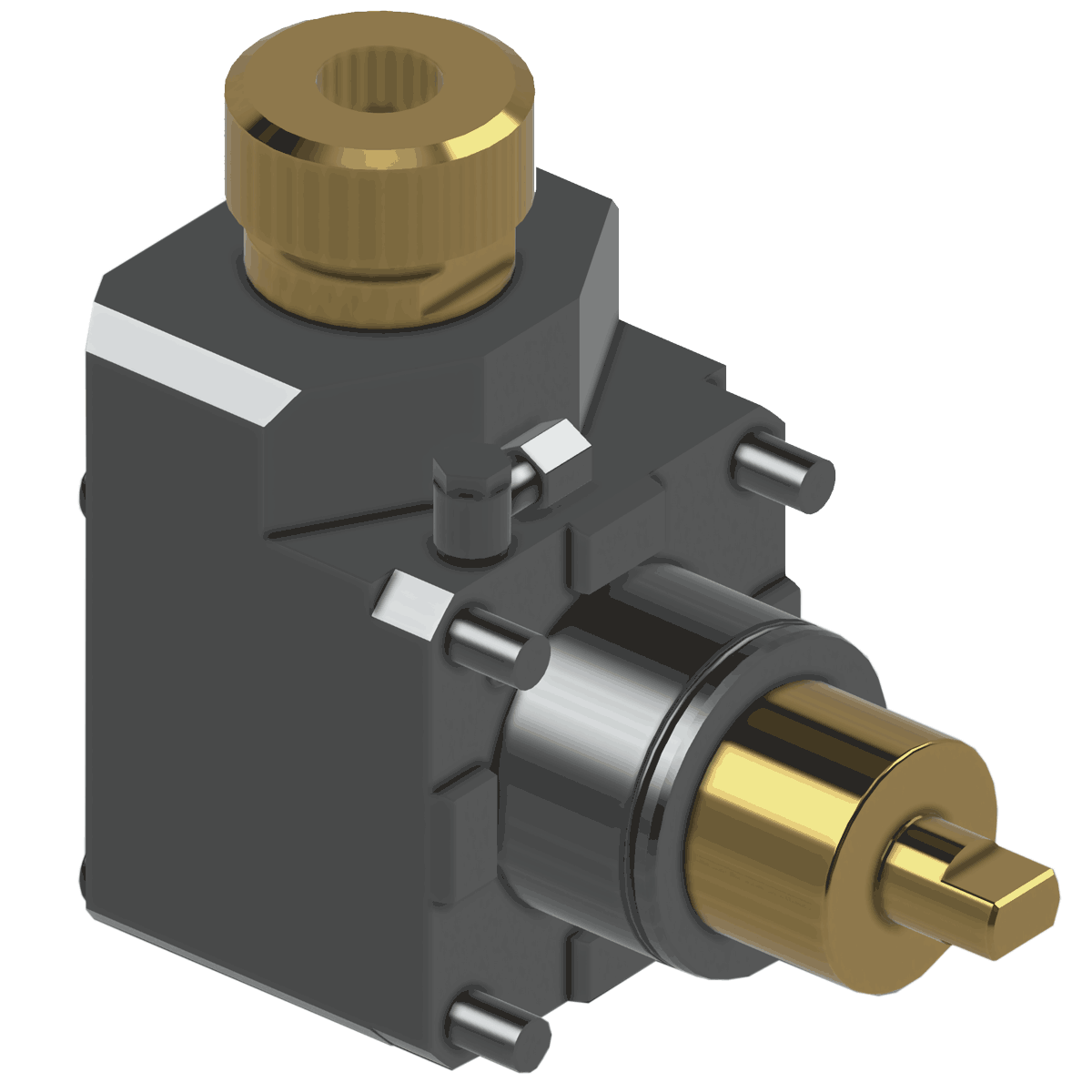

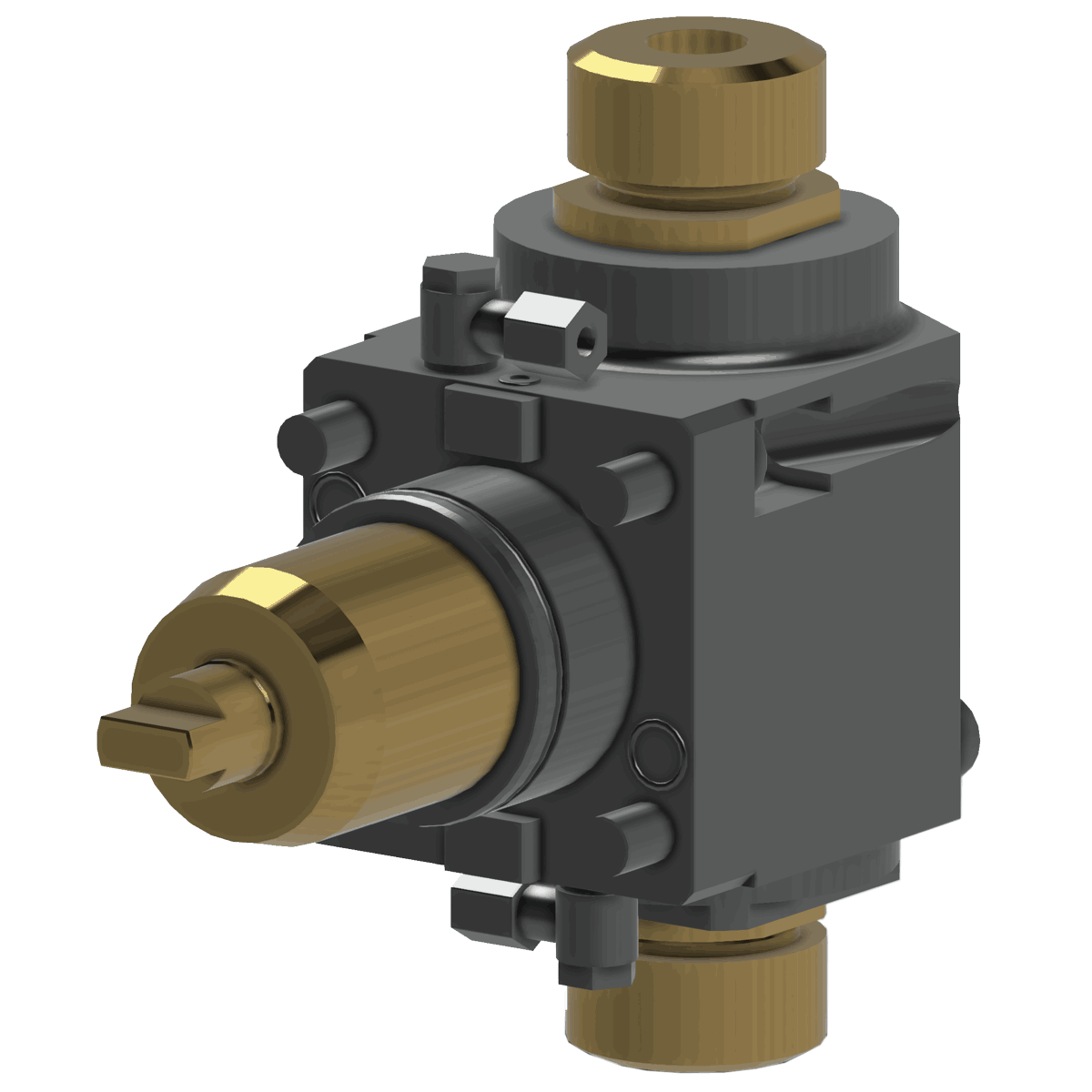

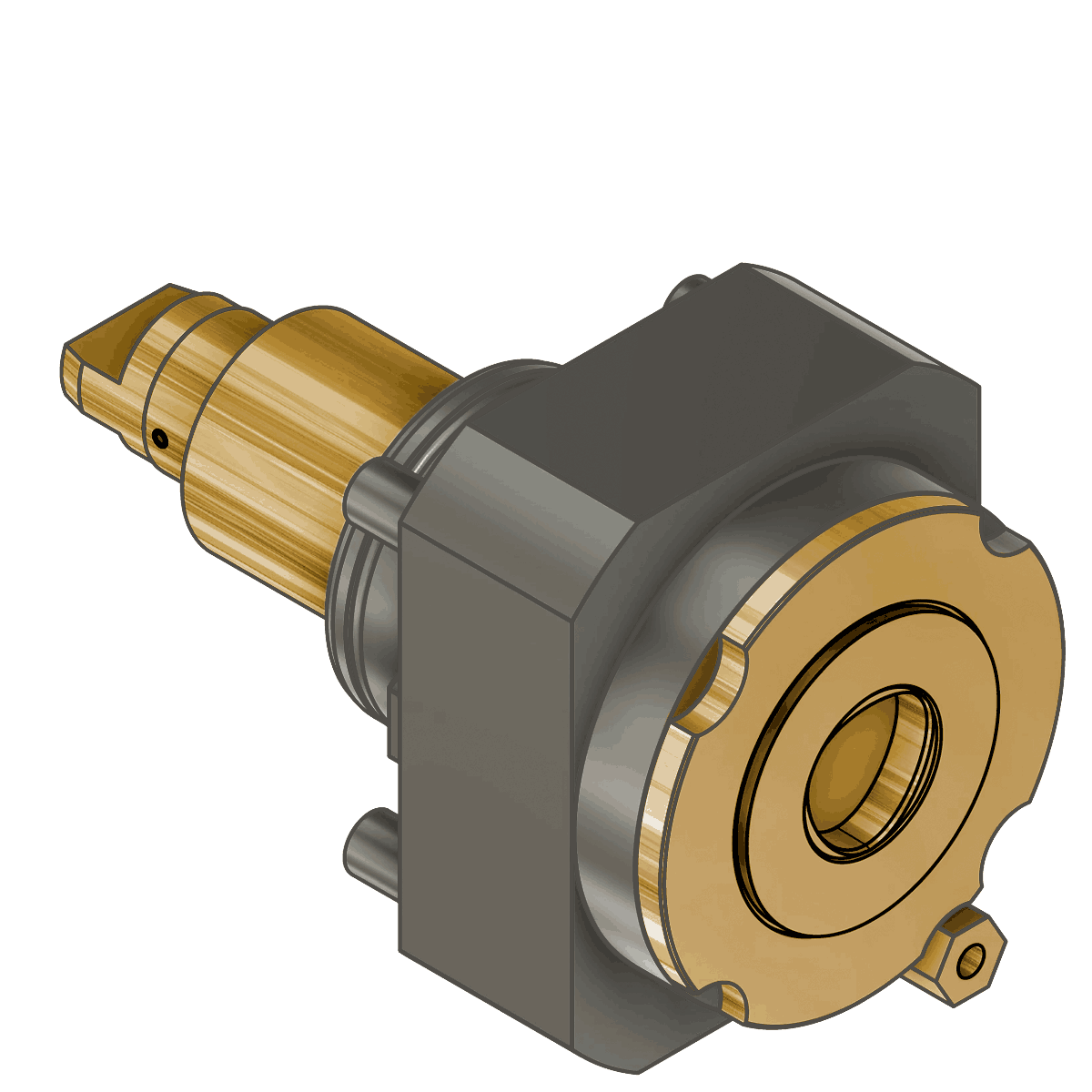

Every unit is dismantled and pre-inspected before work commences. The Driven Tool is then thoroughly cleaned and degreased. We carry out a close inspection of all the components. Bearings and seals are replaced and upgraded where appropriate, before it is regreased and sealed.

Our purpose-built clean-room is the hub of our driven/live tooling services. At NTR, we invest in the right equipment to ensure your machine runs true.

- T.I.R measurement +/- 0.001mm accuracy

- Noise monitoring

- Temperature variation

- Step speed running-in

- Full certification and tool history

Concentricity and alignment checks are then carried out before the Driven Tool is finally rig tested by our qualified engineers. It is then logged on a register and the replacement parts documented against the date when the tool is to be next serviced. The tool is then returned to you in a ready for use state.

You can expect a 7 day turnaround from order confirmation, with a rapid 48 hour response service available on request.

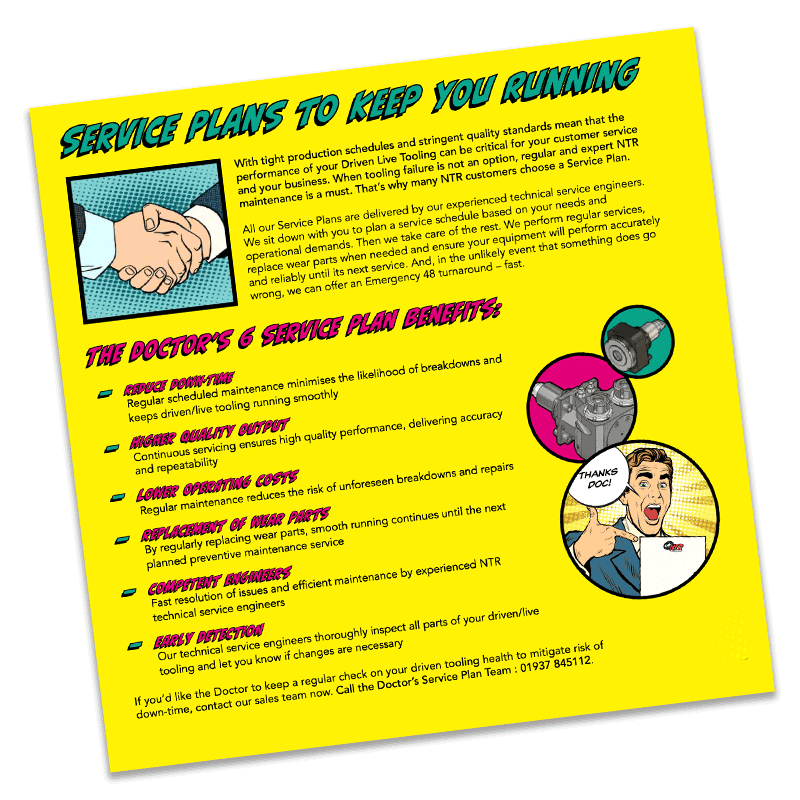

With an NTR Service Agreement for Driven/Live Tooling you are de-risking your production capabilities. With tight production schedules and stringent quality standards mean that the performance of your Driven Live Tooling can be critical for your customer service and your business. When tooling failure is not an option, regular and expert NTR maintenance is a must. That’s why many NTR customers choose a Service Plan.

All our Service Plans are delivered by our experienced technical service engineers. We sit down with you to plan a service schedule based on your needs and operational demands. Then we take care of the rest. We perform regular services, replace wear parts when needed and ensure your equipment will perform accurately and reliably until its next service. And, in the unlikely event that something does go wrong, we can offer an Emergency 48 turnaround – fast.

REDUCE DOWN-TIME

Regular scheduled maintenance minimises the likelihood of breakdowns and keeps driven/live tooling running smoothly

HIGHER QUALITY OUTPUT

Continuous servicing ensures high quality performance, delivering accuracy and repeatability

LOWER OPERATING COSTS

Regular maintenance reduces the risk of unforeseen breakdowns and repairs

REPLACEMENT OF WEAR PARTS

By regularly replacing wear parts, smooth running continues until the next planned preventive maintenance service

COMPETENT ENGINEERS

Fast resolution of issues and efficient maintenance by experienced NTR technical service engineers

EARLY DETECTION

Our technical service engineers thoroughly inspect all parts of your driven/live tooling and let you know if changes are necessary

Manufacturers & Brands

Alberti, Algra, Benz, Big Daishowa, Eppinger, EWS, Gerrardi, Heimatec, Mario Pinto, OMG, Sandvik, Star to name but a few…

If your OEM is not listed, then please contact us and we can discuss your requirements.