How to Use Frequently Asked Questions?

FAQs : TOOLING RECLAMATION

- How do I get a quote for my tooling repair?

- Can you arrange a courier to pick up my items?

- What if I need my tooling ASAP?

- What happens if you can’t repair my tooling?

- Has BREXIT changed the way you operate within Europe?

- Can the NTR Tooling Refurbishment be part of our ISO:4001 Certification?

- I am in mainland Europe, can I still use this service?

The process is simple.

| 1) Send in a photo/description of the tool or send the damaged tool to us

We will look at the type of tool, size, and damage to provide a quotation – Please bear in mind, some tools when they are sent into us will need to be checked before quotation to see if they are eligible for repair |

| 2) We send the quotation to you

We will send you a Quotation via email with the costs for the repair. If you have sent the products into our factory, you will also receive an order number. We will also inform you about any tools that may be scrap, or if we need any spares for the tools to be able to continue with a repair. |

| 3) You accept the quotation

When you have responded to our email that you are happy with the repair, we will proceed with your order. You will need to attach a Purchase Order to this email to confirm. |

| 4) Repairs

Your tools will go through a process of Stripping down, Welding, Milling, Fitting, Inspection, Shot Blast/Black Etching and one final inspection before being sent back to you. You will receive an inspection certificate to verify dimensions of the tool. |

| 5) Tool Return

Your tool will be carefully packed and shipped back to you. We will send you an email to let you know and you will be able to track your order as travels back to you. |

It really couldn’t be easier!

Of course!

Since the COVID epidemic the majority of our work is now collect/delivered using a courier service. Not only is this way of working a safer method for you and your colleagues, we can also easily track deliveries and ensure the return of your tooling in a timely manner.

If you would like advice on the courier procedures at NTR, please get in touch and we will send you our templates to ensure the most efficient use of these services.

Equally, if you are local or passing by Wetherby, we are happy for you to drop tools off with us.

We know that sometimes tooling repairs can be business critical. Production lines, manufacturing operations and project deadlines can all suffer when machines are down. Our Express Service has a 24/48 hour turnaround which means you can be back up and running quickly and without too much disruption to your business.

Not only can NTR provide a speedy solution to your issues, we can also help with de-risking future issues by manufacturing similar tools so you are not reliant on just one tool. Our design engineers can take existing tools and create exact replicas giving you multiple tools in stock. Now if one tool smashes, you have a replacement and we can be working on the broken tool so you are always covered.

Our expertise means we can even design out issues or improve a tool with extra pockets and inserts for example, to improve productivity. Contact us, we are here to help.

On rare occasions, damage is so great that we cannot repair the tool. You may also find that as we have repaired the tool many times before there is not enough material remaining for us to regrind.

In cases like this your options are simple.

- Our engineers can create new tooling for you, using an existing model to reverse engineer from. At this point, we will discuss your requirements and design out some of the inherent flaws.

- Alternatively, as one of our valued customers we can contact our sister company to supply you with a replacement at a very reasonable cost.

In both cases, the scrappage of the original tool will be calculated and off-set against whichever route you wish to take with us!

Like every other company across the UK, we were unsure as to how the changes from Brexit would effect NTR and our customers across Europe. We worked hard to put new procedures in place in readiness for the new measures and that work paid off.

Within a few weeks, our services were running at the same lead-times as pre-Brexit and all initial complexities had been successfully navigated.

If you would like advice on how best to work with NTR from Europe, please get in touch with our Customer Services Team who can issue you with guidelines and templates.

Absolutely, yes! We are all becoming acutely aware of our environmental actions and the damage caused to our planet. The ISO 14001 Certification: Environmental Management sets out a criteria to provide assurance to company management, stakeholders that their environmental impact is being measured and improved.

By coming to NTR for all your tooling refurbishment and repair needs, you are in effect recycling your tools and lessening your environmental impact on the planet.

As a company NTR recycle all waste and use ecologically sound companies to deal with scrapped tools and waste products such as metallic swarf. We are firm believers in making a difference to the planet wherever we can.

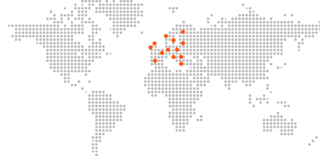

We have been serving Europe for many, many years and continue to do so on a daily basis. We have agents and distributors across the continent who are the main point of contact for companies in need of our tooling and refurbishment services.

Our excellent courier services, mean that you can send us your damaged tooling from across the world and you will receive the same seamless service as those closer to our Headquarters.

Our European network includes:

- Belgium

- Finland

- France

- Germany

- Ireland/Eire

- Italy

- Netherlands

- Norway

- Poland

- Slovenia

- Spain

- Sweden

Don’t see your country of residence? Don’t worry with the assistance of our courier service we can provide our services no matter where you are located. Simply contact us and we will advise of all import/export procedures for your particular country.

FAQs : NEW TOOLING

- What materials do you use in manufacturing New Tooling?

- What is your capability for large scale projects and production?

- What tolerances do you work to and how do I know that my tooling will be right?

- Can you help to design and redevelop New Tooling?

- I am in mainland Europe, can I still use this service?

At NTR we are able to work various materials, metals and plastics. Please see our materials section for more information.

Can’t see the specific material you require? Call us. We have a strong relationship with many material suppliers who will be happy to source the required product.

Our Engineers, Planning Teams and Operations Team can work with you to discuss your requirements for large scale projects. We can deliver to tight deadlines and at an appropriate rate to work within your project roadmap.

Our Precision Engineers provide the reassurance of consistency and quality when producing a large quantity of tooling and other components.

If you would like advice on how NTR can provide assistance with large scale projects, please get in touch and our Team will discuss your requirements in detail and provide advice.

We work to very tight tolerances as part of our work for the Nuclear and Aerospace sectors. If your project requires similar controls, then we act accordingly.

Our Quality Controls are rigorous and all tooling, components and fixtures leave NTR having been carefully checked, certified and signed off.

On rare occasions, damage is so great that we cannot repair the tool. You may also find that as we have repaired the tool many times before there is not enough material remaining for us to regrind.

In cases like this your options are simple.

- Our engineers can create new tooling for you, using an existing model to reverse engineer from. At this point, we will discuss your requirements and design out some of the inherent flaws.

- Alternatively, as one of our valued customers we can contact our sister company to supply you with a replacement at a very reasonable cost.

In both cases, the scrappage of the original tool will be calculated and off-set against whichever route you wish to take with us!

We have been serving Europe for many, many years and continue to do so on a daily basis. We have agents and distributors across the continent who are the main point of contact for companies in need of our tooling and refurbishment services.

Our excellent courier services, mean that you can send us your damaged tooling from across the world and you will receive the same seamless service as those closer to our Headquarters.

Our European network includes:

- Belgium

- Finland

- France

- Germany

- Ireland/Eire

- Italy

- Netherlands

- Norway

- Poland

- Slovenia

- Spain

- Sweden

Don’t see your country of residence? Don’t worry with the assistance of our courier service we can provide our services no matter where you are located. Simply contact us and we will advise of all import/export procedures for your particular country.

FAQs : LIVE TOOLING

- Do you provide a servicing solution for Driven Tooling or Live Tooling?

- What are your lead-times for Live Tooling repair?

- Which brands of Live Tooling are you able to repair/service?

- How do I get a quote for Live Tooling repair/servicing?

Yes, we do.

Our Live Tooling Servicing & Maintenance contracts are an integral part of our customer’s manufacturing/production operations. We provide a regular servicing agreement that provides peace of mind and guarantees continuation of service for your business.

Depending on the level of use of your machinery, we can provide 3, 6 or 12 month servicing for your Live Tooling. Whatever your requirements to ensure the smooth running of your operations, and to reduce the risk of down-time, we are happy to work with you on your requirements.

We know that a small monthly cost to improve the longevity of your Live Tooling makes more economical sense than the loss triggered by loss of productivity and component replacement. Call us today and we can discuss your requirements as a matter of urgency!

Our in-house expertise at NTR allows us to provide a speedy and efficient service to our Live Tooling customers. We have been working in this specialist area for many, many years and enjoy a good relationship with parts distributors as part of our supply chain.

All lead-times are dependent on the specific requirements for each job but our average turn-around is as follows:

There are many Live Tooling manufacturers and we cover most of them:

Eppinger, Alps, MT Marchetti, Eroglu, Benz, Evermore, Heimatec,

EWS, Mario Pinto, Zettle Mimatic, Madaula, OMAP, Romai, Wagner,

Parlec, Bristol Tool, Alberti, Gerrardi, Wendel, Sauter, Algra,

WTO, Holdwell to name but a few…

If your OEM is not listed, then please contact us and we can discuss your requirements.

Quickly maximize timely deliverables for real-time schemas. Dramatically maintain solutions. Efficiently unleash cross-media information without cross-media value. Efficiently unleash cross-media information without cross-media value. Quickly maximize timely deliverables. Efficiently unleash cross-media information without cross-media value. Quickly maximize maximized timely deliverables for real-time schemas. Dramatically maintain solutions.

Dramatically maintain solutions. Efficiently unleash cross-media information without cross-media value. Quickly maximize timely fixed deliverables for real-time functional schemas.

Need Support?

CALL US

(+44) 01937 845 112